![]()

Short pasta

![]()

Long pasta

![]()

Filled pasta

![]()

Double pasteurization

![]()

Stabilization

![]()

Freezing process

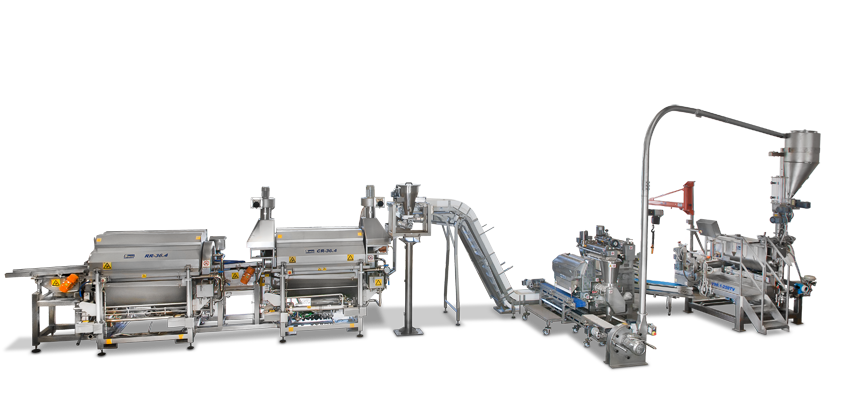

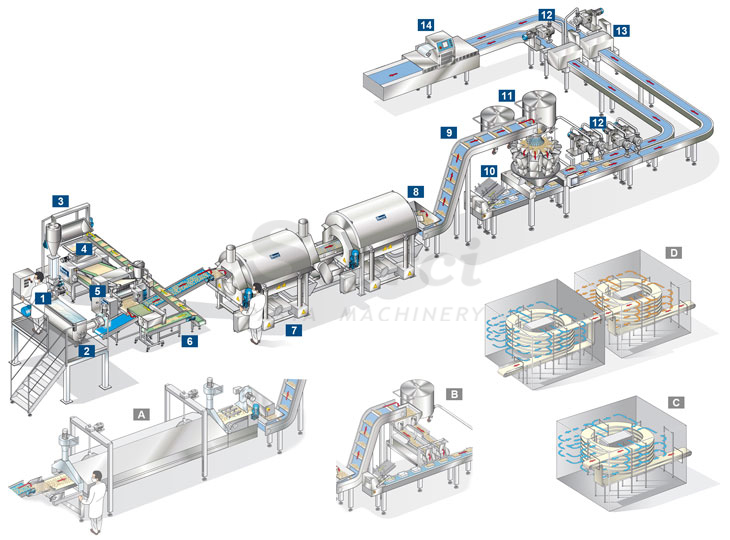

The best solution for you is R2E, a unique line for producing short, long and filled pasta. The beginning of the line is flexible and enables to produce pasta using a press and/or dough sheeter: if these are total vacuum machines by Storci, the cooking quality is guaranteed. The lines have been designed and created with a special attention to the cleanliness and hygiene of each detail, with capacities ranging from 600 to 5000 trays/hour. Great productions can be reached increasing the number of tray rows and using interchangeable metallic plates that have been shaped according to the trays dimensions. Packaging is also possible if the heat-sealer film is attached onto the same machine. The revolving cooking and cooling systems guarantee a wide range of working times in a limited area cover; you will be able also to cook dry pasta, rice, meat, fish and vegetables to expand your product range. A winning choice for your business.

Play the video

Wide choice of shapes: short, long, filled pasta. Great capacity of production. Cooking in small area cover. Great simplicity of usage and cleaning.

![]()

Long, short, filled pasta line can be customized according to your needs. Several options are available that make it suitable for any requirements.

We have stored all the information that you can find in this page, together with other useful tips, in a easily readable document. Download our brochure clicking here below. You will need Adobe Reader.