Special unit for the correct recovery of the fresh pasta scraps produced at the beginning of production, during shape changeover operations, filled pasta off-cuts, etc. Allows the user to obtain pasta scraps which can easily be re-kneaded with excellent results.

Play the video

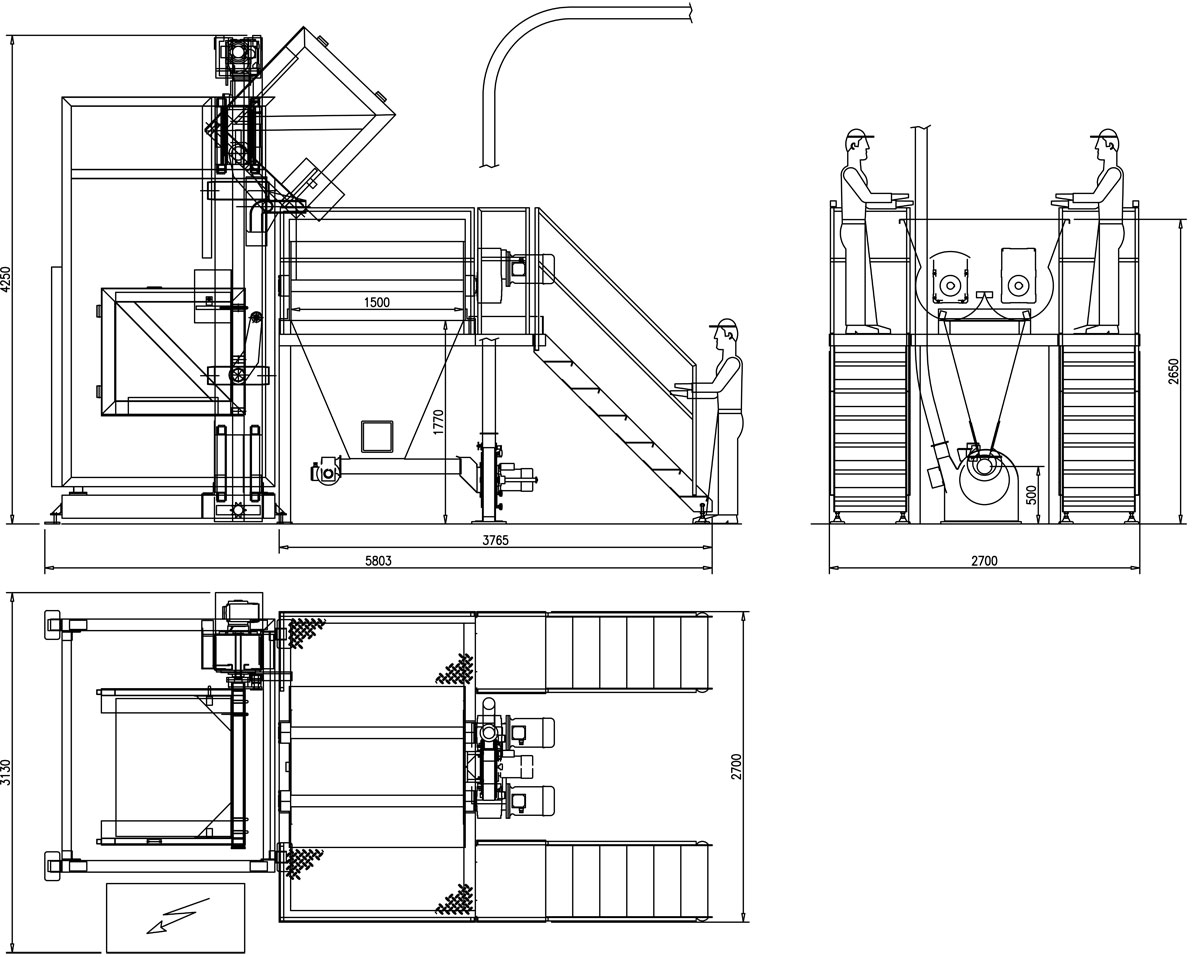

| REC 1002 C/A/I | ||||

|---|---|---|---|---|

| MODEL | POWER (kW) | LENGTH OF PIPING (m) | GRINDING CAPACITY (kg/h) | DIMENSIONS (LxPxH) |

| REC S | 26.5 | 20 | 600-700 (*) | 2700x5800x4250 |

| REC M | 30 | 28 | 600-700 (*) | 2700x5800x4250 |

| REC L | 37.5 | 40 | 600-700 (*) | 2700x5800x4250 |

Dimension and technical date are not binding. Storci S.p.A. reserves the right to modify them without notice.

Note: the data provided is purely indicative and not binding as it may be subject to the variability of products and the line in which units are installed.

(*) for products with a dry surface and maximum, evenly distributed, humidity of 30%.