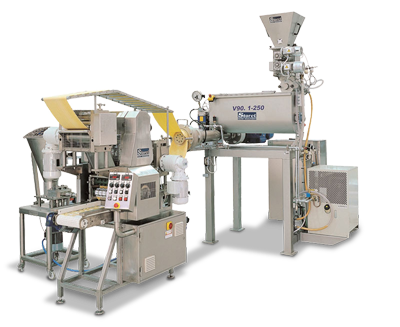

Press in stainless steel suitable for the production of dry and fresh pasta, particularly right for the automation of laboratory and small firms. It allows automatic production without worker presence.

| Production (kg/h) | 250-300 |

| Power consumption (kW) | 11 |

| Installed power (kW) | 12 |

| Weight (kg) | 800 |

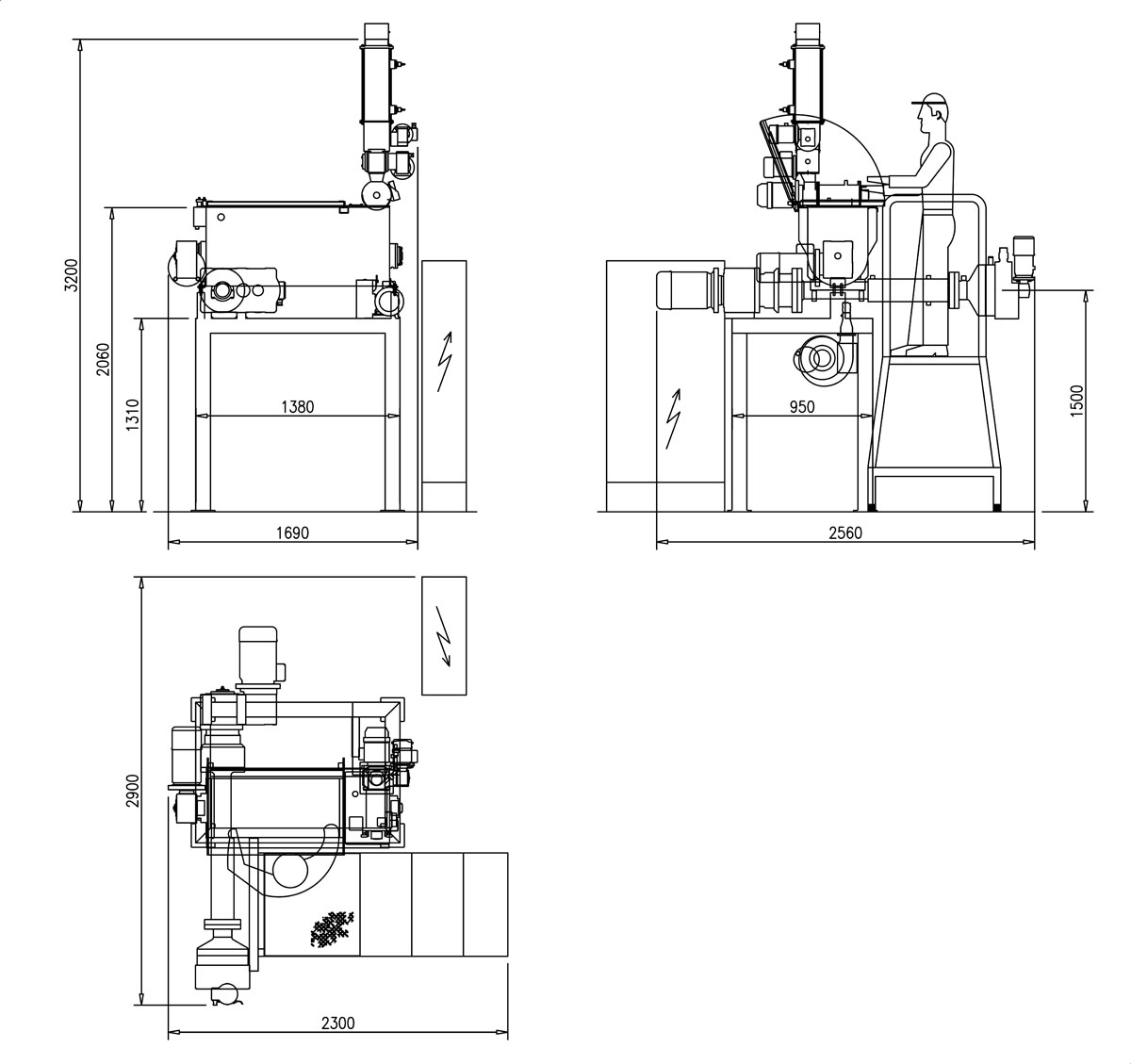

| Sizes (mm) | 240x3112x2131 |

| Mixing tank capacity (lt) | 86.8 (65 Kg) |

| Die dimension (mm) | 250x234x60 |

Dimension and technical data are not binding. Storci S.p.A. reserves the right to modify them without notice.