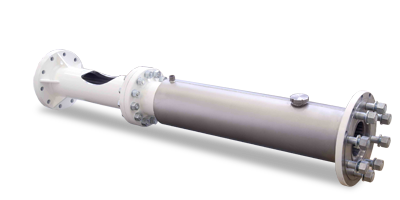

The compression stage is one of the most important technological stages in determining the end quality of the pasta. Minimizing the increase in temperature during the compression stage is fundamental for ensuring excellent firmness of the pasta during cooking. The compression unit is made up of one or more worm screw and one or more internally grooved cylinder. The cylinder is essential for optimum screw operation. The play between the worm screw and the cylinder must always be kept within set limits in order to avoid dough expulsion or rotation which lowers the quality of the dough and lead to a fall in production.

One of all advantages of our cylinders:

We recondition used compression cylinders in our workshop. This process involves:

Or:

For cylinders you can opt for simple servicing or the application of the latest technology (upgrading) for components considered technically obsolete.

.

Very important: with regards cylinder wear, a cylinder is to be considered worn, and consequently in need of replacement, when the grooving in the area directly downstream from the infeed mouth has completely worn away.

For quick and easy inspection, when the press is stopped, put your hand in from the vacuum tank and check the state of the grooving in the point indicated (fig. A). When the grooving has almost totally worn away, the compression cylinder must be replaced or reconditioned. This operation can be carried out with the worm screw installed or removed.

A more accurate inspection can be carried out by measuring, (fig. B) with the aid of a suitably sized gauge, the diameter of the screw and the cylinder. When the difference between the two diameters exceeds 12/10 mm, the compression unit must be replaced or reconditioned. This operation must be performed with worm screws removed.

.