Automation of tray stacking on the drying trolleys at the end of short-cut or special shape pasta lines can be achieved by using a tray stacking machine positioned at the end of the line.

Use of the trays stacking machine, which makes it possible to reduce the number of personnel involved in running a short-cut and/or special shape pasta line (packing operations excluded) to just two operators, must always be coupled with a tray feeder from which it receives the trays full of pasta to be dried in the static drying cells.

It is equipped with an alarm for signaling when the trolley has been filled and comes complete with perimeter safety panels.

Alternatively the Robo XI robotized system is also available.

| ROBO-T | |

|---|---|

| Trays dimensions (mm) | 1200x600x55 |

| Speed (trays/min.) | 2-4-6-8 |

| Power installed (kW) | 1.1 |

| Area (sm) | 3.6 |

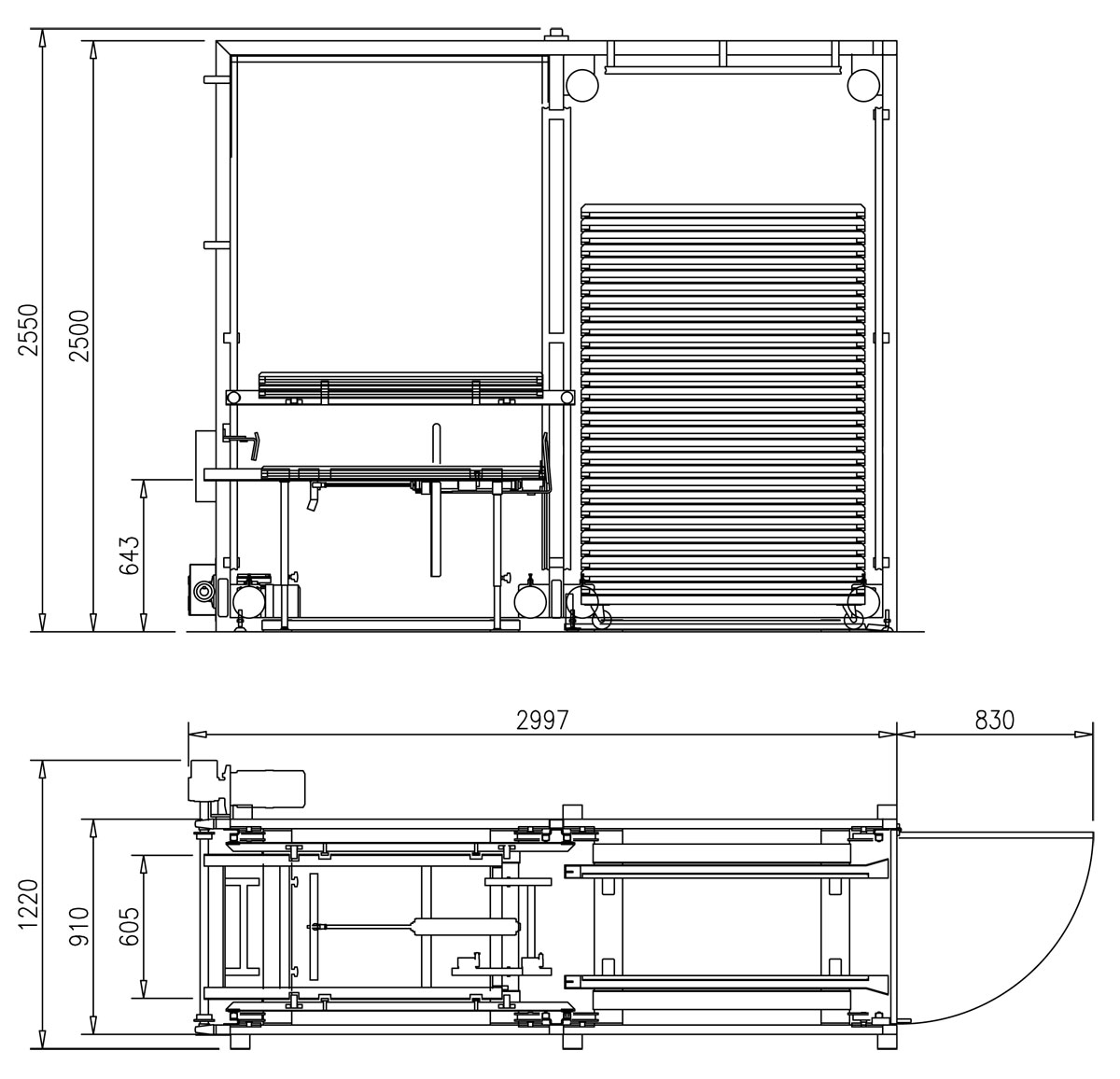

| Size LxPxH (mm) | 2997x1220x2550 |

Note: the data provided is purely indicative and not binding as it may be subject to the variability of products and the line in which units are installed.