Designed to dry all types of short- and long-cut pasta, special pasta, nested pasta and lasagna by simply wheeling in the trolleys filled with trays or sticks. The best scratchproof and rustproof guarantee for high resistance to heat and humidity, made with the same panels successfully used in the large automatic Fava Storci pasta lines. Suitable for temperatures exceeding 90° C which make it possible to dry pasta at high temperatures. Equipped with stainless steel wheeled trolleys for trays or sticks, with various tray heights available for all types of product, ranging from 70 mm for large shapes to 30 mm for lasagna. The sticks are entirely made of anodized aluminium with Z-shaped hooks, in order to guarantee perfect stability of the product during the various drying phases. Special versions are always available on request, such as cells with double-wing doors for a shorter opening radius. Sturdy and hard-wearing, bucking the current trend of lowering quality to keep prices down: the best compromise cost, quality and service life.

| Cell type | No. of Trolleys | No. of trays H=30 mm for lasagna |

No. of trays H=50 mm |

No. of trays H=70 mm |

No. of sticks L=580 |

No. of sticks L=1120 |

Dimensions AxB-H Trays 1200x600 Sticks L=580 and L=1120 |

Absorbed power (kW) |

|---|---|---|---|---|---|---|---|---|

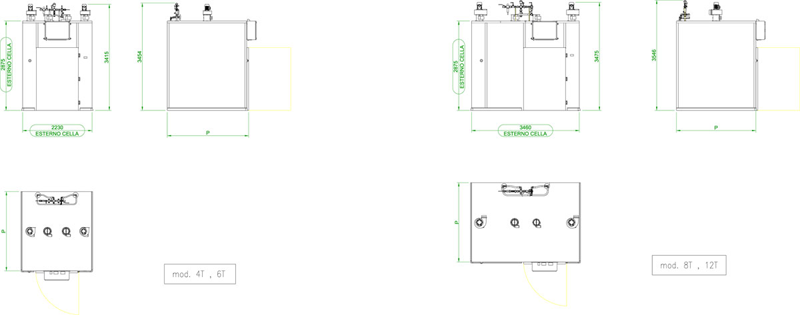

| HW 4 T | 4 | 240 | 132 | 104 | 720 | 180 | 2230x2550-3460 | 3,3 |

| HW 6 T | 6 | 360 | 198 | 156 | 1080 | 270 | 2230x3765-3480 | 5,5 |

| HW 8 T | 8 | 480 | 264 | 208 | 1440 | 360 | 3460x2550-3550 | 6,6 |

| HW 12 T | 12 | 720 | 396 | 312 | 2160 | 540 | 3460x3765-3550 | 8,8 |

Note: the data provided is purely indicative and not binding as it may be subject to the variability of products and the line in which units are installed.